When I first tried to write this article, the title I wrote was “how I saved $140,000 dollar for my client”, however, instead of telling another successful story, I think it would make better sense for the readers and especially for the suppliers to get to know the reasons behind the failure, thus let’s view from the opposite angle, and see what we can gain and learn from this lesson.

Years ago, I have received a special task from a friend of friend (words of mouth), who wanted me to negotiate a better price and payment term from his supplier, as he was looking to buy their state-of-the-art machines, this supplier was the inventor and the exclusive producer of this machine, so they insisted on their price and business term very firmly without any compromise. The situation was pretty like “Take it or Leave it”, however, supplier was very confident that the client would take it as he came to visit the factory specially and also shown great interest in this unique machine. Therefore, the situation was very passive for the buyer and myself.

Let’s see how we handled this case and eventually turned things around.

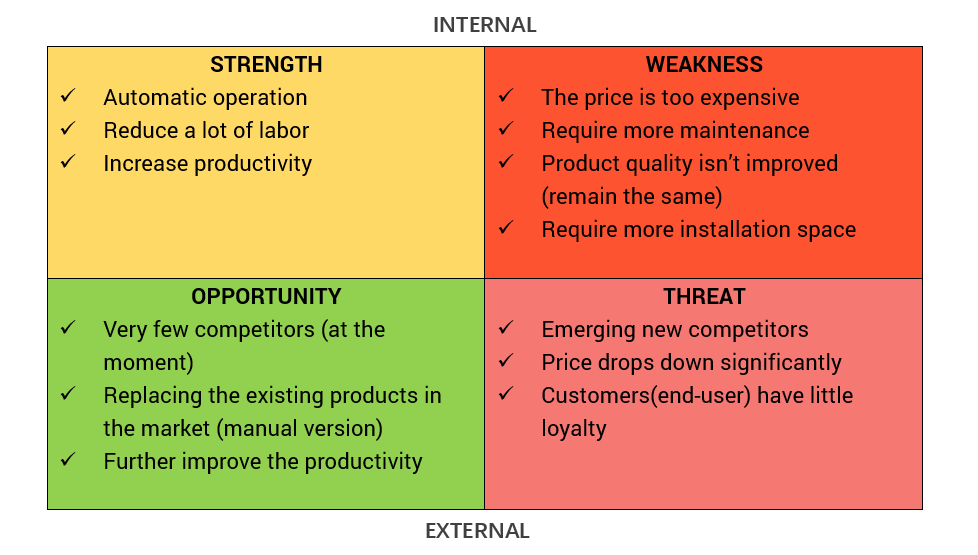

First of all, I made a SWOT analysis for that supplier, see below:

Secondly, I did a deep sourcing for getting more solid proof to support my analysis and “fight back” to supplier, I took two points for illustration.

- Price, I prefer VALUE, as the value decides your price. I checked with more than 15 suppliers across nearly the whole mainland China, from the south to the north, and as per my research, the major production area is northern cities like Tianjin, Jinan, Suzhou); from the manual version to semi-automatic version and to automatic version (I finally found an alternative); I was aware that this supplier marked up the price too much, it’s much higher than any type of competitor (between 20% to even 55%), base on the similar parameters, the price was at least 20% higher

- Quality, it includes both the maintenance risk and production quality.

- As per my research, this type of automatic machine contains a lot of hydraulic devices and that was the first machines in the market, there was not available customer reference (project), as customer, we were paying for the risk;

- Production quality actually remains the same as traditional manual production, as I figured out the whole production process was quite similar as what the labor did, thus no difference for the finished product quality.

In conclusion, this was a nice machine, automatic & productive, BUT it was overpriced too much, it’s not worthy to its value. When I shown my analysis and figures to supplier, they were shocked, by my swift finding and also the deep understanding about their product and market. However, unfortunately they still made a wrong judgement and blindly insisted on their offer at the end, which resulted in we ceased the negotiation and switch to my alternative supplier who could offer 20% lower price with a certain% balance payment credit, even more attractive, the new machine can improve the annual production capacity by up to 25% more!! That’s a happy ending for my client, but it’s a tragedy for that supplier who completely screw up a business worth $700,000 USD.

Let’s get back to the topic of how they screw this up, see below:

1. Lack of understanding about your competitor and market, this is a common issue for many suppliers, especially for the manufacturers, they mainly focus on product and order, they know very little about their competitors except for belittling or even slandering the competitors. In this case, that supplier did not even know someone had already developed a better machine than theirs, they still indulged in the false “No.1” title.

2. Overconfidence, I would prefer to describe “Blind Confidence” in this case; again, that supplier knew very little about the general market price, probably they did not agree with that it is the VALUE decides the PRICING. During the negotiation, they always insisted on the exclusive design of the product instead of realizing the real VALUE of the product.

3. Strategic misjudgment, due to the above lack of understanding about competitors and market price, which made them misjudge the position in the whole negotiation (they wrongly positioned higher themselves), never under-estimate your counterparts, include your competitor and customer

4. Being too tough (not flexible), from the very beginning to the end, the most used words from this supplier was “NO, because ……” they always tried to defend themselves and defeat the other. I have to say being too tough in negotiation does NOT help in most of times; in my principle, I prefer “draw” rather than win/lose, it is too academic (or MBA) to say WIN-WIN (I don’t personally think it really exists), in Chinese we say 和(hé), it means harmony, compromise or draw. A mentor once said that during negotiation, try to let your counterpart feel win. In this case, if that supplier knew a little bit skill, then they would not drive me into a corner.

Alright, that is all for today. Actually, it was not that easy to convince the client and switch to a new supplier, I’d love to share these in my another article in the coming weeks. If you like this article, keep following my update at www.denissourcing.com